Farmers’ gains hinge on curbing post-harvest losses

HORTIculture has been recognised as a sunrise sector due to its potential as an economically viable and sustainable alternative to agriculture. It not only promotes efficiency in land use but also creates opportunities for employment, particularly for the youth in rural areas. Data published by the National Horticulture Board shows that India produced about 312 million metric tonnes (MT) of fruits and vegetables in 2021-22 and is ranked second overall in the world after China. The country is ranked first in the production of banana, mango, papaya and okra. In recent years, India has witnessed a shift in terms of the area from foodgrains towards horticultural crops, which have outpaced the former in production. Better income for farmers due to urbanisation and higher consumption of fruits and vegetables are the driving force behind the increase in the output of horticultural crops.

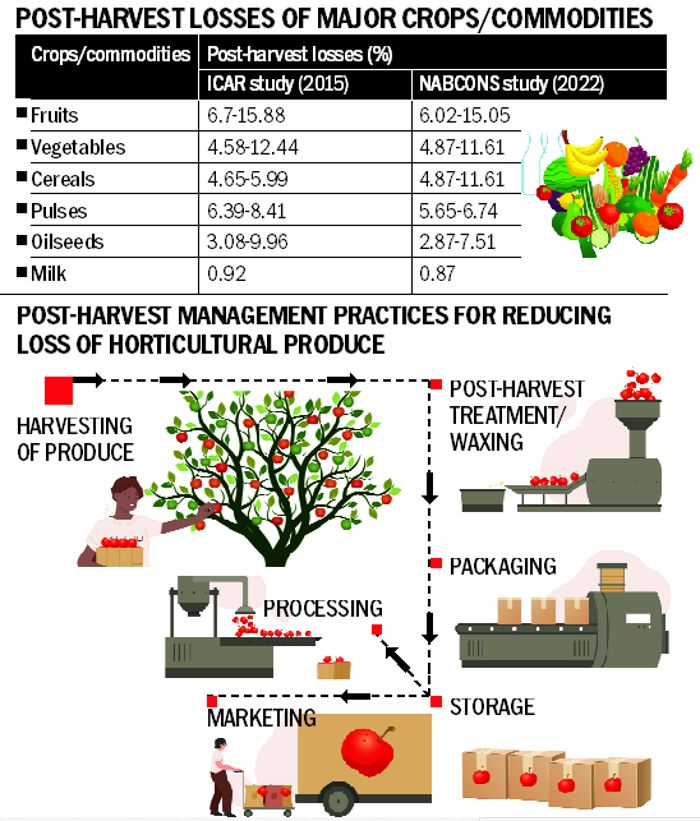

The farmer, who has been reduced to a producer, can be transformed into a producer-processor. Curbing post-harvest losses is increasingly being seen as a sustainable way to achieve global food and nutritional security. Keeping in view the potential of horticulture in India, a demand-driven cold chain, processing facility and market linkage needs to be created, connecting farmers to the consumers. This will not only cut down spoilage but also retain the quality of the harvested products, ensuring a better income for farmers and a cost-efficient delivery to the consumers.However, post-harvest issues, particularly the development of cold chain and processing infrastructure, have not been strategically addressed for safe handling of the perishable produce. In India, the value addition is only 8-10% compared to 23% in China, 45% in the Philippines, 88% in the UK, 30% in Brazil, 70% in the US and 82% in Malaysia. On the one hand, India is the world’s second-largest producer of vegetables and fruits, but on the other, substantial wastage (6-15%) of these crops is reported in the country. Many a time, a demand-supply mismatch for horticultural commodities contributes to widespread price fluctuations, inflation and ultimately huge post-harvest wastage.

Whenever there is overproduction of a crop, be it tomato, potato, peas or onion, it leads to protests against the crash in market prices; farmers incur both post-harvest and monetary losses. In India, as per a report of NABARD, food worth Rs 92,651 crore is lost during the post-harvest stage before it reaches the consumer. The major contributory factors for such losses of fruits and vegetables are:

- Lack of awareness about post-harvest handling operations

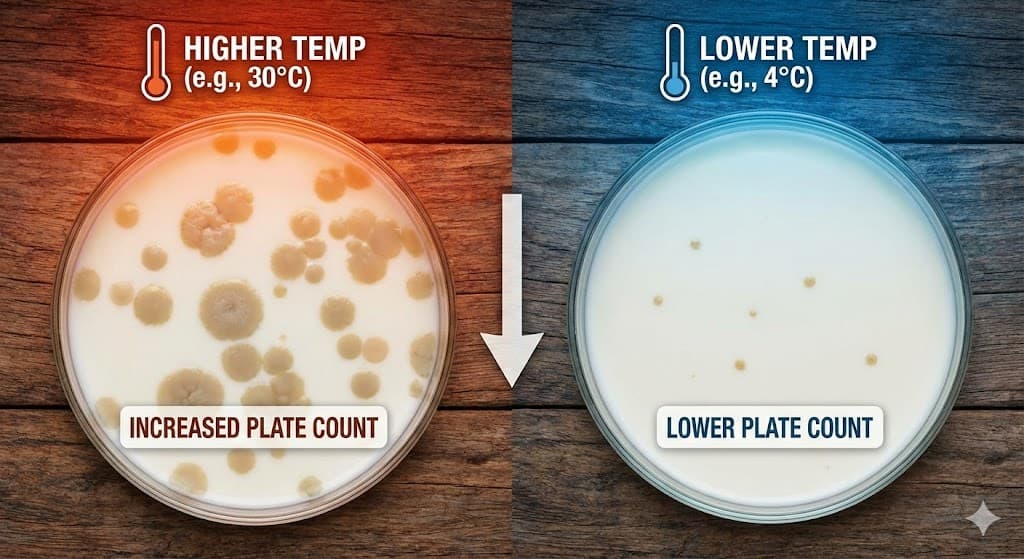

- Gaps in the cold chain or insufficient cold storage capacity

- Poor processing and marketing infrastructure

The Ministry of Agriculture has initiated the Mission for Integrated Development of Horticulture, under which cold chain development is the thrust area. The Ministry of Food Processing Industries is running the ‘Scheme on cold chain, value addition and preservation infrastructure’. Farmers or entrepreneurs need to contact the Departments of Horticulture or Agriculture for getting benefits from these schemes.

Cooperatives can play a key role in the post-harvest management and marketing of fresh produce. Himachal Pradesh Horticultural Produce Marketing and Processing Corporation Ltd (HPMC) has become a role model for the apple industry in India. The National Dairy Development Board has established outlets for fresh fruits and vegetables in New Delhi. Cooperatives such as Mahagrapes and Mahamango in Maharashtra are other instances of success stories. Apni mandi (farmers’ market) is a good example of producers selling their produce directly to consumers. The formation of produce clusters is an important step to be considered for preventing a glut-like situation during the harvesting season of a particular commodity. Further, strengthening the clusters with packhouse, sorting & grading facilities, cold storage and refrigerated transportation for distant marketing of the produce would help in maintaining a regular supply chain of fresh produce.

The Punjab Government has established citrus, litchi and pear estates to boost the production and marketing of these fruits to distant markets. For processing of the leftover produce, the medium-scale primary processing centre should be established in these clusters. For example, a freezing unit for peas, carrot, cauliflower, and capsicum; a dehydration unit for chilli, methi, mint and coriander; and a juicing-pulping unit for fruits as per norms of the Food Safety and Standards Authority of India (FSSAI). Creating awareness among farmers about packhouse operations such as grading, packaging, storage and processing will help in minimising the post-harvest losses and boosting the marketing of the perishable produce.

The farmer, who has been reduced to a producer, can be transformed into a producer-cum-processor. Curbing post-harvest losses is increasingly being seen as a sustainable way to achieve global food and nutritional security. Keeping in view the potential of horticulture in India and the significant volume of fruits and vegetables being transported between the states or exported, a demand-driven cold chain, processing facility and market linkage needs to be created, connecting farmers to the consumers. This will not only reduce spoilage but also retain the quality of the harvested products, giving the farmers a better income and guaranteeing a cost-efficient delivery to the consumers.

Source : The Tribune Oct 30th 2023 by BVC Mahajan and Satbir Singh Gosal, Mahajan is Director, Punjab Horticultural Post-harvest Technology Centre, and Gosal is Vice Chancellor, Punjab Agricultural University, Ludhiana