Highlights

- •Psychrophilic AcoD from CW and DM can replace fossil fuels in the dairy industry.

- •Cheese whey and dairy manure can be mixed 65:35 % w/w at 20 °C.

- •Cheese whey and dairy manure can produce 562 mL CH4/gVS.

- •About 44% of the associated emissions to dairy industry are reduced.

- •Citric acid is the largest contributor to the carbon footprint.

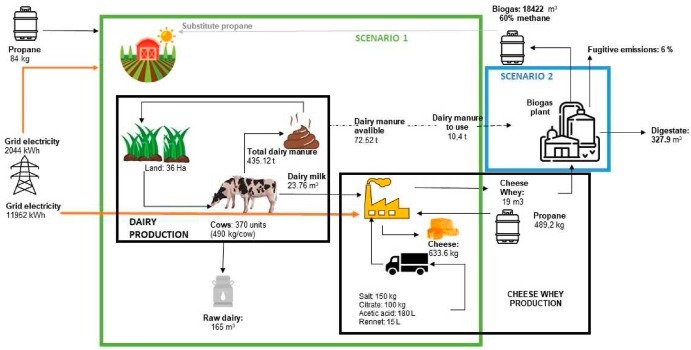

Cheese whey (CW) and dairy manure (DM) are the main residues from the dairy industry, both of which can led to significant negative environment impacts if not properly managed. However, their combined anaerobic digestion represents an opportunity to obtain bioenergy and a stabilised material as a soil improver on the farm. Biochemical potential of methane (BMP) assays were carried out at psychrophilic conditions (20 °C) to analyse the influence on biomethane production of different CW:DM mixtures (% w/w) at different of inoculum-to-substrate ratios (ISR). Based on the BMP results, a life cycle assessment (LCA) of the cheese manufacturing process was carried out considering two scenarios (i) considering the current process, where propane gas and electricity are used for cheese production (ii) the incorporation of the biogas generated in the cheese production process in the company. BMP results showed that the best mixture between CW and DM was 65:35 (weight basis) at an organic load of 0.6 gVS/L (ISR of X). The LCA showed that CW and DM anaerobic digestion allowed to reduce the cheese manufacturing carbon footprint from through the substitution of propane by the biogas produced, changing from 5.5 to 3.1 kg CO2-eq/kg cheese produced, which indicates that according to the monthly production (633.6 kg) it would stop emitting about 1519 kg CO2-eq, i.e. a saving in terms of emissions of approximately 43,6% of the total currently generated.

Introduction

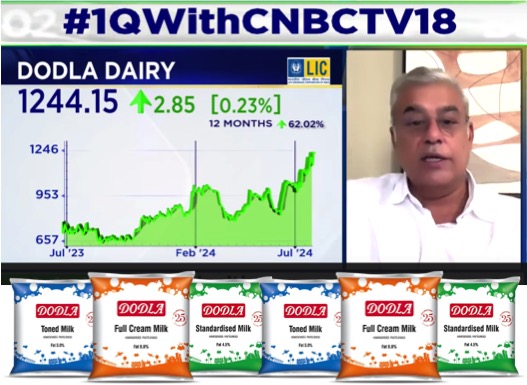

Milk and dairy industry products are largely produced and consumed worldwide. According to FAO (2022), 930 million tons of milk were produced in 2022, 0.6 % more than in 2021. The largest milk producers in 2022 were Asia (419 million tonnes), Europe (232 million tonnes), North America (112.6 million tonnes), and South America (65.6 million tonnes). In South America, milk production decreased by around 1.7% from 2022 to 2021 due to lower production in some countries (e.g. Brazil, Uruguay and Argentina), which was partially offset by increases in Colombia (FAO, 2022).

Cheese production generates a by-product known as cheese whey (CW), which is produced at a rate of 9 L/kg of cheese (Prazeres et al., 2012). This by-product has an acidic pH (3.9–4.5), low alkalinity (<0.22 g/L CaCO3), high organic matter content (50–102 g COD/L), phosphates (2.0–4.5 g/L), inorganic nitrogen (1 g/L) (Asunis et al., 2020; Valdez Castillo et al., 2020). Considering these characteristics, if the CW is sent to water bodies can induce eutrophication processes, derived from the change in the biogeochemical cycles of phosphorus, iron and nitrogen as a consequence of the alteration of the redox balance; as well as changes in the soil structure as it affects its physical and chemical structure (Valdez Castillo et al., 2020).

Another residue inherent to the dairy industry is cattle manure, also known as dairy manure (DM). DM is estimated to be produced at a rate of 8 kg per 100 kg of cattle (Martí-Herrero, 2019). DM is characterised by a pH near neutrality (6–8), high organic matter concentrations, and a total nitrogen concentration of 3–4 g/L (Neshat et al., 2017). DM is also a major source of pollution, especially in tropical regions since manure degradation results in the emission of ammonia (NH3) and methane (CH4).

Several studies have reported the successful anaerobic co-digestion (AcoD) of CW and DM for the production of renewable biogas energy and a stabilised material suitable for crop fertigation (Escalante et al., 2018; Mandavgane and Kulkarni, 2020). AcoD is the anaerobic digestion of two or more substrates that are complementary to each other, such as CW and DM. The production of biogas through anaerobic digestion represents an option to decarbonise the dairy industry while providing a suitable technological solution for residues management. However, the AcoD of these two substrates is limited by the acidic nature of CW and potential accumulation of volatile fatty acids (VFAs) as a result of the presence of rapidly biodegradable organic matter in CW (González et al., 2022). In this regard, DM high alkalinity helps maintaining circumneutral pH values and preventing process inhibition by low pH.

Several authors have evaluated the AcoD of CW and cattle manure using BMP tests. Bertin et al. (2013) obtained the best ratio at 50:50 v/v (CW:CM) with a production of 320 mLCH4/gVS under mesophilic conditions (35 °C), Labatut et al. (2011), studied different proportion between CW and DM finding productions of 237 and 252 mLCH4/gVS to proportion of v/v de 90:10 y 75:25 of DM and CW at 35 °C, on the contrast Jaimes-Estévez et al. (2020) reported the highest methane yield of 420 mLCH4/gVS at 70:30 v/v (CW:CM) under psychrophilic conditions (15 °C),

Previous research (Jaimes-Estévez et al., 2022) shows that it is possible to obtain valuable by-products from CW and CM, as it has been shown that it is possible to obtain bioenergy from them; in addition, the energy obtained could be reintroduced into the production process, thus contributing to the circular economy concept. On the other hand, studies have been published analysing different aspects of the AD process of this type of waste, however, studies on the environmental analysis necessary for decision making and implementation, especially in low temperature farms, are scarce (Nleya et al., 2023; Wang and Zhou, 2023).

Anaerobic digestion research usually take place at mesophilic (35–37 °C) and thermophilic (50–55 °C) conditions, which incur energy costs that sometimes cannot be covered. Accordingly, authors such as Martí-Herrero et al. (2022) and Rodríguez-Jiménez et al. (2022), highlight the need to work at psychrophilic temperatures (≤20 °C), since 88% of the world’s population lives in places where temperatures are considered to be psychrophilic, such as the highlands, where most dairy farms are located, so operating digesters at temperatures below 20 °C avoids the need to heat reactors. It is also necessary to continue to study this temperature range if the installation of low-cost digesters is to become more widespread and, in this sense, it refutes the misconception that the psychrophilic range is insufficient to produce energy.

In this sense, tools such as life cycle analysis (LCA) can contribute to show the reduction of environmental impacts in terms of avoided emissions. For example, Glover et al. (2023) highlight that it is possible to reduce the warming potential of DM management in 80% from 361 to 73 kg CO2-eq per 1000 kg, by converting a system where liquid DM is managed in an anaerobic lagoon and solid manure is piled, to an anaerobic reactor that degrades CM. Gosalvitr et al. (2019) simulated the AD process of CW from cheddar cheese and found that in a conventional scenario, the impact is 14 kg CO2-eq/kg cheese, but if the biomethane from the AD process is considered, the impact is reduced to 2%, and by focusing on the cheese a greater reduction can be achieved, which is related to the management of manure from dairy cows. However, there is little information on the use of this class of substrates as energy substitutes, contributing to current global problems in terms of energy while at the same time reducing GHG emissions, so an estimation of the life cycle analysis could contribute to making this type of biological process viable (Esteves et al., 2019). Thus, it is necessary to evaluate the AD of these substrates under psychrophilic regime from the technical and environmental point of view in order to justify the implementation of these projects in real scale (Amado et al., 2021; Mosquera et al., 2021).

The aim of this study was to perform an environmental and technical evaluation of the anaerobic co-digestion process using CW and DM substrates from the dairy industry. To achieve this objective, biochemical methane potential (BMP) tests were carried out in the psychrophilic regime (20 °C), evaluating different mixing ratios and inoculum-substrate ratios (ISR). The results were used to estimate the amount of biogas that could be produced by using all the CW generated in the company and the DM needed to carry out the co-digestion process were used. Finally, the amount of greenhouse gases that would not be emitted if these substrates were used on the farm was estimated.