Accountability in Food Safety Starts at the Top - Fingertip in ice cream

Dear top management of Food establishments , if a finger is found in a food product, the responsibility doesn't fall on your team—it falls squarely on you."

In a shocking incident in India, a consumer recently discovered a fingertip in a packaged ice cream, raising grave concerns about food safety standards and practices in the country. This horrifying discovery not only highlights a severe lapse in the food manufacturing process but also underscores a disturbing disregard for human welfare in the pursuit of profit. It is imperative to address such issues with utmost seriousness and urgency, ensuring that stricter food safety norms are enforced globally to prevent such inhumane and dangerous occurrences.The Incident: A Case of Gross Negligence

The incident involved a factory worker who lost a part of their finger while working on the production line. Instead of halting operations to locate the missing fingertip and address the injury properly, the factory continued its production. Consequently, the fingertip, along with traces of blood, ended up in a batch of ice cream that was later distributed to consumers. This blatant disregard for both the worker's health and the consumer's safety is a stark reminder of the potential human cost behind negligent food safety practices.Global precedence of similar Food safety negligence

In a news item in NBC news on May 3rd 2005, in North Carolina, a customer found an employee's severed fingertip in frozen custard. The worker, Brandon Fizer, accidentally inserted his finger into a machine, leading to the incident. Despite immediate medical attention, the fingertip ended up in a customer's order. The state's Department of Labor is investigating compliance with safety regulations.

Such incidents are rare but alarming. In 2003, the U.S. recorded 5,620 nonfatal fingertip amputations in workplaces, with only a few occurring in food-related industries. Yet, even a single incident can have severe health implications, including the risk of hepatitis B.

Past incidents include a false claim in California where a woman alleged finding a fingertip in Wendy's chili and a genuine case in Ohio where a man found human skin in an Arby's sandwich. These incidents reveal gaps in workplace safety and food handling protocols.

The recurrence of such events demands immediate action. Enhanced training, regular audits, and strict penalties for non-compliance are crucial. The food industry must prioritize human safety over profits to prevent these inhumane and dangerous lapses.

The Rapid Alert System for Food and Feed (RASFF)

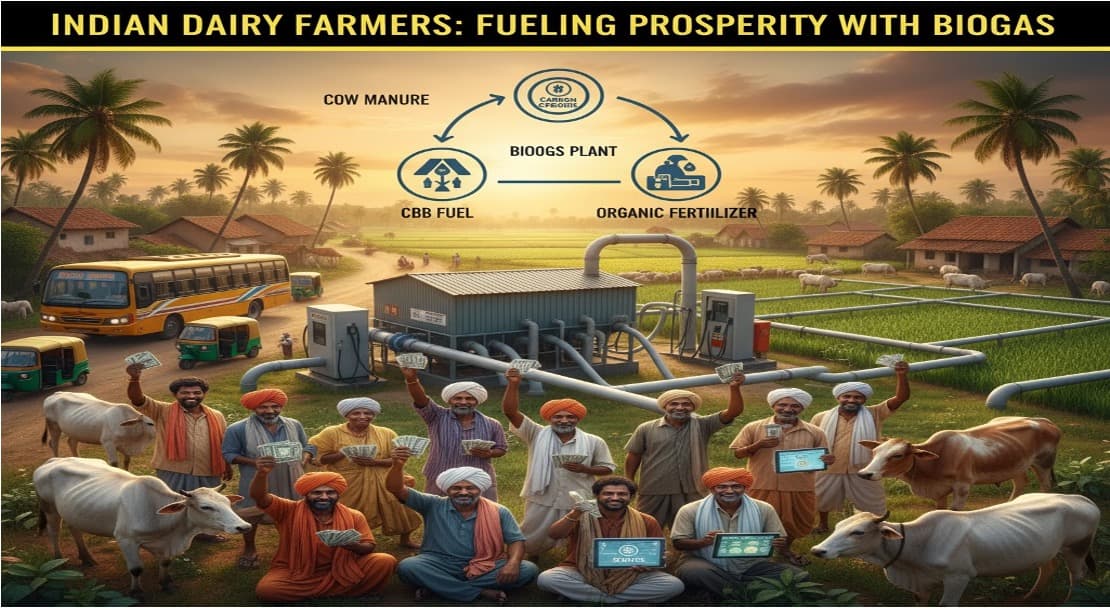

The study analysed growth in global dairy sector and highlighted that the increased milk production has heightened concerns about safety and authenticity. Contaminants, as defined by Codex Alimentarius, include any unintended substances present in food due to various stages of production, processing, and environmental contamination (Codex Alimentarius Commission (CAC), 1995). Deliberate contamination, such as the 2008 melamine incident in China, also poses risks, emphasizing the need for thorough screening and testing throughout the dairy supply chain (Gossner et al., 2009).

Contamination in the dairy supply chain can occur at any stage, introducing hazards like toxins, physical hazards, pesticides, heavy metals, veterinary drugs, and organic pollutants (Colak et al., 2007; Fischer et al., 2011a, 2011b; Jooste et al., 2014; van Asselt et al., 2016, 2017). Fraud detection is challenging, as adulterants evolve. Traditional methods, such as adding water to milk for economic gain, are now countered by advanced detection technologies (Singh and Gandhi, 2015). Regulatory bodies and companies conduct checks to monitor contamination and fraud (Thompson and Darwish, 2019; Ulberth, 2020).

This study aims to review recent safety and fraud issues in the dairy sector (2015–2019). The Rapid Alert System for Food and Feed (RASFF) provides access to food and feed safety information to prevent unsafe products from reaching consumers (European Commission, 2019b). For fraud issues, the HorizonScan database collects information on emerging food fraud and safety issues from over 100 food safety authorities and sources (Fera, 2019b). Scientific literature and grey literature, such as news articles and reports, were also reviewed to identify developing threats not mentioned in these databases.

This leads to our million dollar question.. Who is building database of such incidents including accidents at food factories involving any kind of amputation ?

Global Food Safety Standards: A Comparative Perspective

In contrast, many countries have implemented stringent food safety regulations to prevent such incidents. For example, the United States enforces the Food Safety Modernization Act (FSMA), which mandates proactive measures to ensure food safety across all stages of production and distribution. Similarly, the European Union adheres to strict food safety protocols under the European Food Safety Authority (EFSA), which emphasizes risk assessment and management to safeguard public health.These frameworks are designed to prevent contamination, ensure proper handling of food products, and mandate immediate corrective actions in case of any breaches. The emphasis is on a proactive approach, with regular inspections, robust reporting mechanisms, and severe penalties for non-compliance.

The Need for Stricter Norms in India

India, while having its own set of food safety regulations under the Food Safety and Standards Authority of India (FSSAI), needs to adopt more rigorous enforcement mechanisms.Thorough Risk Analysis Under HACCP: Preventing Biological and Other Hazards in Food Products

A thorough risk analysis under the Hazard Analysis Critical Control Point (HACCP) system is essential for proactively preventing biological and other hazards in food products. HACCP is a systematic, science-based approach that identifies specific hazards and measures for their control to ensure food safety from production to consumption. The steps detailed in the following paragraph are well-known but are unfortunately followed by only a few plants.A thorough risk analysis under the Hazard Analysis Critical Control Point (HACCP) system involves several key steps to proactively prevent biological, chemical, and physical hazards in food products. First, hazard identification is crucial, determining potential hazards at each stage of food production, from raw material acquisition to final consumption. Next, identifying Critical Control Points (CCPs) where control is essential, such as during cooking, cooling, and packaging, helps to eliminate these hazards. Establishing critical limits, such as specific temperatures and times that must be maintained at each CCP, ensures effective hazard control. Continuous or periodic monitoring of CCPs, through temperature checks, visual inspections, and testing, is vital for compliance with critical limits. Developing corrective actions for addressing deviations ensures any process issues are promptly corrected and prevented from recurring. Verification procedures, including audits, testing, and record reviews, confirm the effectiveness of the HACCP system. Finally, detailed record-keeping of all procedures, monitoring, corrective actions, and verifications ensures traceability and accountability.

The way forward

It is deeply concerning that the essential first step of hazard identification is often missing in many dairy and food plants in India, including medium to large establishments. Among the seven golden principles of HACCP, hazard analysis, verification procedures, and monitoring with detailed record-keeping play the most critical roles in ensuring food safety.To truly grasp the gravity of this issue, I urge you to ask your food safety team for details on the hazard identification being carried out at your plant. You will likely find that documents on verification and monitoring, along with trend analysis, are scarcely available. This glaring oversight highlights a systemic failure that can lead to severe food safety incidents.

Even the HACCP consultants bear a significant responsibility in preparing companies for food safety, ensuring that all processes comply with stringent standards and that hazard identification, verification procedures, and detailed record-keeping are meticulously followed. However, certifying agencies also play a crucial role and must not neglect their duty to thoroughly verify documentation. When certifying agencies fail to scrutinize records and processes, they undermine the integrity of the HACCP system, potentially allowing severe food safety lapses to occur. Both consultants and certifiers must uphold their responsibilities diligently to ensure the highest standards of food safety are maintained.

Food regulators must mandate that Food Safety Officers prioritize checking FSMS documentation and records of verification procedures and monitoring, rather than merely creating pressure on Food Business Operators (FBOs) for lifting of samples. An FSO is expected to be thoroughly knowledgeable about food safety and HACCP protocols and should act as a safety coach for the FBO rather than merely policing operations. Without rigorous adherence to these HACCP principles, the risk of biological, chemical, and physical hazards in food products remains alarmingly high. It is imperative that we address this issue with the seriousness it deserves to protect consumers from preventable foodborne illnesses and mental torture as in the case of this finger incidence along with other hazards.

The incident in India serves as a grim reminder of the urgent need to strengthen food safety norms and practices. It is a call to action for regulatory bodies, food manufacturers, and consumers alike to demand and ensure higher standards of safety and hygiene. The race for profits should never come at the cost of human welfare and safety. By implementing stricter norms, conducting regular audits, and fostering a culture of safety, we can prevent such inhumane incidents and ensure that the food we consume is safe and produced with the utmost care and responsibility.

Swipe to continue reading

Previous Article

Next Article