Case Study: mooMark Private Limited – Transforming the Dairy Supply Chain

Introduction: mooMark, headquartered in Bengaluru, Karnataka, was founded in 2020 with a clear vision to revolutionize the dairy supply chain through technology-driven solutions. The company initially focused on B2B milk procurement but expanded its scope in 2023 to include value-added products and private labeling services. mooMark’s mission is to support farmers, dairy, and FMCG brands by ensuring traceability and quality at every stage of the milk supply chain.

Challenges in the Milk Supply Chain: mooMark encountered several operational challenges hindering its digitization efforts across the dairy supply chain:

- Farm: Lack of proper farm records and unregistered cows made it difficult to trace milk back to its source.

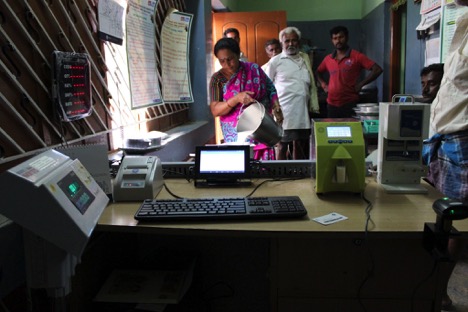

- Collection Center: Manual record-keeping and outdated technology systems led to inefficiencies and errors in milk collection.

- Chilling Center: Resource-intensive chilling activities and inadequate monitoring increased the risk of contamination and pilferage.

- Transportation: Tracking the route and volume of milk during transportation posed logistical challenges.

- Processing: Capturing real-time data and ensuring quality control at processing units were major hurdles.

Table 1: Technologies deployed by mooMark

| # | Technology/ Application | Stakeholder | Purpose |

| 1 | mooON | Farmers and Extension/ Intervention Agents | Herd management |

| 2 | ActiTrak | Farmer | Cattle activity monitoring |

| 3 | smartFarms | Farmer | Digital milk passbooks, financial services, and agricultural input services |

| 4 | smartAMCU mobile application | Collection Center | Automatic milk collection |

| 5 | smartCC | Chilling Center | Quality checks |

| 6 | ConTrak | Chilling | Monitoring milk chilling |

| 7 | AMCU Portal | Dairy | Tracks quality, quantity, and tanker movement. |

| 8 | Traceability Portal | Processing Plant | Mapping the milk procurement and batch processing data |

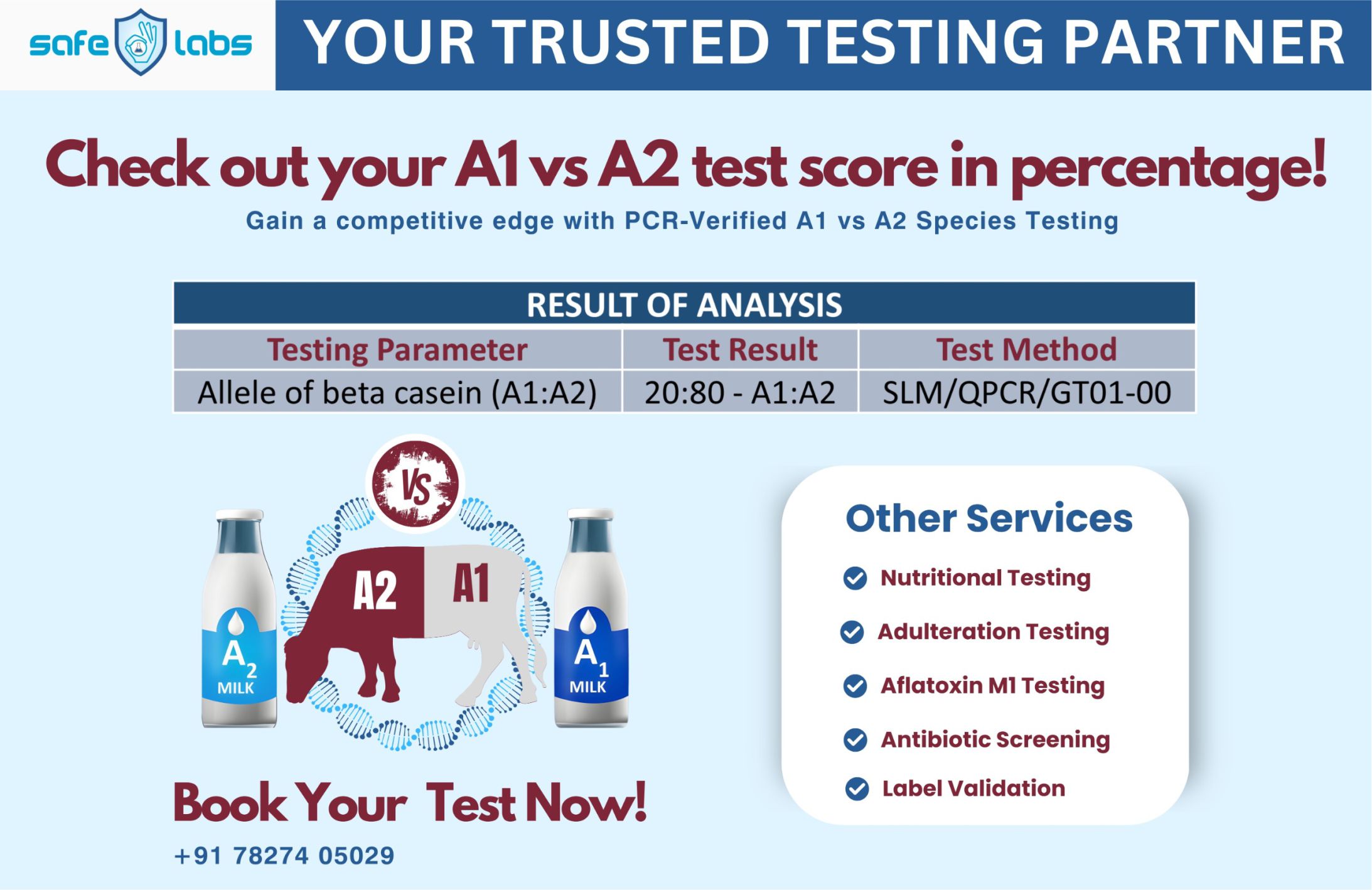

| 9 | Know Your Milk (KYC) | Customer | Trace the milk journey |

Proposed Solutions: In response to these challenges, mooMark implemented various interventions tailored to the dairy industry:

- mooON and ActiTrak: A herd management system for farm monitoring and cow health tracking.

2. smartAMCU: IoT-based automatic milk collection units for precise measurement and quality assessment.

3. smartCC and ConTrak: Real-time monitoring systems for chilling centers to ensure optimal storage conditions.

4. AMCU Portal: A digital platform for monitoring milk transportation and maintaining accurate records.

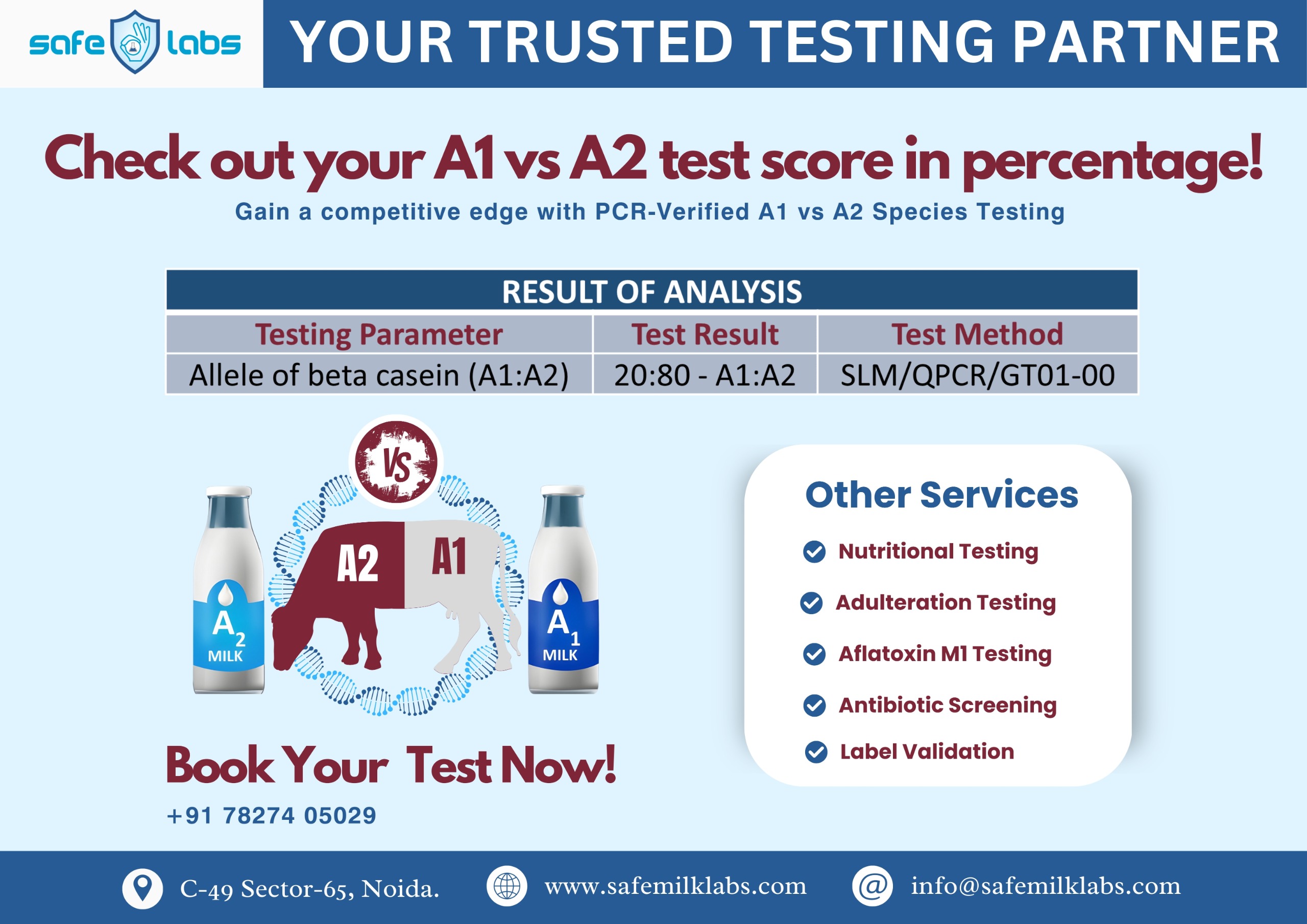

5. Traceability Portal and Know Your Milk (KYM): Systems for quality inspection, batch traceability, and consumer access to milk information.