Solar chillers uplift women dairy farmers in Rajasthan

In a notable move toward sustainable rural dairy, solar-powered milk-chilling units are helping women dairy farmers in Rajasthan reduce wastage and improve incomes — a model increasingly being recognized as a template for climate-resilient dairy development.

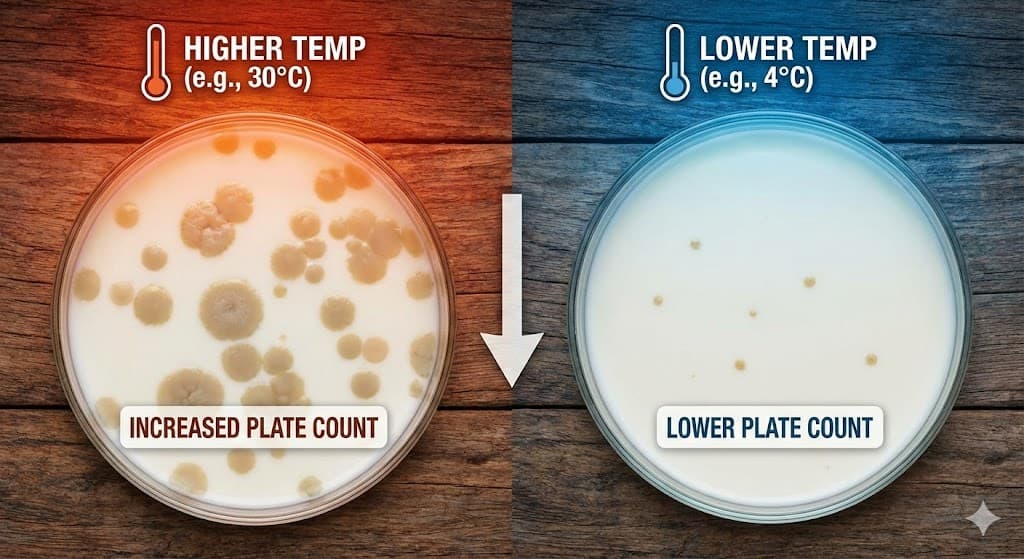

According to the report, these chillers — powered by solar energy (harnessing abundant sunshine) — allow smallholder milk producers (many of them women) to immediately chill collected milk at village-level, preserving freshness and preventing spoilage which used to be common due to low ambient temperature control and long transport times to processing centres. The implementation has reportedly led to substantial reduction in milk wastage and added income stability for participating farmers.

The program targets small and marginal dairy producers, organizing them into village-level milk supply clusters, and deploying solar-powered chilling units that store milk at safe temperatures until it can be transported to dairies. Women, who form a large share of smallholder producers in these clusters, benefit especially — as the chillers allow them to supply their milk on time without quality degradation, and thus receive fair procurement prices rather than losses.

Local cooperative-dairy unions and implementing agencies say that milk-quality improvements and reduced spoilage have increased the volume of marketable milk by as much as 15–20 % over earlier levels in pilot villages — boosting farmer revenues accordingly. Solar chiller adoption is also seen as a step toward energy-efficient, environmentally-sustainable dairy supply-chain in regions where grid electricity is unreliable or absent.

The technology has been deployed through the Asha Mahila Milk Producer Company Limited—a women-led dairy cooperative that began in 2016 with 11 members and has since expanded to 50,000 women across 1,100 villages. The cooperative now collects approximately 150,000 litres of milk daily.

WWF India has funded the chillers, while local dairy centres have contributed building infrastructure such as secure rooms and grid-compatible wiring. The solar units also operate with thermal backup, ensuring cooling continues even when sunlight is limited.Initial feedback from dairy workers indicates increased confidence in supplying larger volumes of milk due to reduced wastage. Cooperative leaders say higher milk quality, measured through improved MBRT (Methylene Blue Reduction Test) scores, has strengthened access to commercial markets.

Across India, WWF has installed more than 100 renewable-energy-powered chillers in five states as part of its cold-chain sustainability programme, totalling 851 kW of solar capacity.

Support for the initiative comes from government & cooperative-dairy programmes promoting renewable energy integration in rural infrastructure. The success in Rajasthan demonstrates how climate-smart, decentralized chilling infrastructure can strengthen dairy livelihoods, especially for women and smallholders, and scale up milk procurement without increasing environmental footprint.

Dairy-sector stakeholders say this model has potential beyond Rajasthan — for arid, high-sunlight, off-grid and remote regions across India — and could play a key role in future dairy expansion under sustainable, inclusive and gender-sensitive frameworks.

Why This Matters — Broader Implications & Opportunities

-

Reduced waste, increased output: By minimizing spoilage through immediate chilling, more of the produced milk becomes marketable — effectively raising overall yield without increasing herd size or input costs.

-

Empowering women & smallholders: Because many small producers are women in rural India, decentralized chilling infrastructure ensures they get fair procurement and stable income — promoting inclusive dairy growth.

-

Sustainability & energy-efficiency: Solar chillers align dairy supply-chain expansion with renewable energy usage — reducing dependence on grid-electricity / diesel generators.

-

Scalability across India: Regions with similar challenges (off-grid, extreme climate, remote supply-routes) can replicate the model — offering a blueprint for resilient rural dairy infrastructure.

-

Better raw-milk quality → improved processed-dairy output: Higher-quality chilled milk improves shelf-life and processing outcomes for downstream dairy (milk, ghee, cheese, powder), benefiting processors and consumers.